Target In Washington Heights

Home » Case Studies » Target In Washington Heights

Target’s 11th store in Manhattan planned for the Washington Heights area faced two potentially show-stopping subfloor challenges. First, the 25,000 square foot floor space was covered with plywood resistant to bonding with subfloor materials. Second, engineers imposed weight limits on the materials to be used to level the store’s substrate. A number of subfloor material makers were consulted before Schönox without answers to these significant challenges. Both issues stood in the way of the needed leveling of the subfloor’s high and low areas as well as preparation of the surface to receive LVT coverings. Schönox worked with Excel Flooring, developing a project plan to address subfloor bonding and weight issues.

Existing Substrate

Fire-treated plywood covered the space, providing a surface which met code requirements, but one with bonding issues for subfloor materials. The store’s second-story position in an older structure presented an outstanding location for Target, but one where engineers limited the weight of subfloor materials used in the space.

Plan

Schönox Renotex® 3D, multi-dimensional fiber reinforcement fabric, paired with Schönox AP Rapid Plus, hybrid active-dry based self-leveling compound, provided the solutions for the project with its floating subfloor system.

Preparation

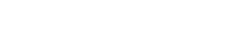

The fire-treated plywood was left in place. High strength, but also lightweight, extruded polystyrene insulation panels were placed in the low spots across the subfloor.

The plywood subfloor was vacuumed and poly sheeting placed across the entire surface with all seams taped, preventing any materials from contacting the plywood.

Schönox Renotex ® 3D was rolled in place, acting as a decoupling layer eliminating any issues with adherence to the plywood or insulation panels.

Leveling

Schönox AP Rapid Plus was mixed in and distributed around the project space, using Portamix tools.

Poured to a depth of at least ½”, Schönox AP Rapid Plus moved and self-leveled across the Renotex® 3D fabric.

The subfloor was poured in sections across the project site. Schönox RS 50 Foam Tape was used to provide a barrier around the pour, decoupling the leveler from walls and vertical structures.

Schönox AP Rapid Plus’s hybrid active-dry technology allowed the leveler to dry independently of job site temperature and humidity conditions.

Ready for foot traffic in 2 to 3 hours and floor covering in 16 hours at the ½” depth, Schönox AP Rapid Plus provided a smooth, strong surface ready for LVT adhesive.

Floor Covering

With the subfloor issues fully overcome, LVT floor tiles were installed, providing a durable top surface above the Schönox subfloor system.

Renovated Subfloor – Going from Here to There

From fire-treated plywood with bonding issues and subfloor weight restrictions to a floating subfloor construction using Schönox AP Rapid Plus over Renotex® 3D and an LVT top surface.

We believe continuing education is the cornerstone to understanding new technology and techniques to better help with your next project.

We believe continuing education is the cornerstone to understanding new technology and techniques to better help with your next project.